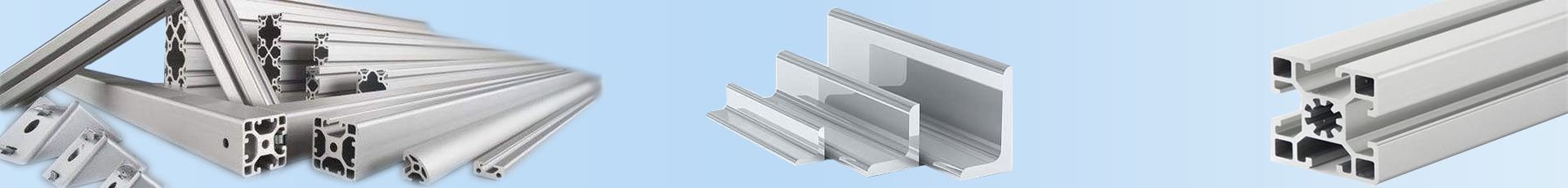

We know that aluminum alloy building profiles can be divided into base materials, anodized profiles, current coating profiles, powder coating profiles, fluorocarbon coating profiles, threading thermal insulation profiles, glue injection thermal insulation profiles and so on. Engaged in the aluminum profile industry for nearly 20 years, someone will always ask me about how to produce the aluminum profile? What is the relationship between various aluminum profiles? Now I will use a diagram to illustrate the production process of aluminum profile and the relationship between profiles.

1. The production premise of aluminum profile is extrusion material. The shape of round ingot is changed from extrusion to profile. For the manufacturer, if the extrusion material is produced, it means how much of the product has been completed, and the subsequent process will be easy. You can tell the customer the specific delivery time.

2. Oxidation profile and electrophoresis profile are produced in one workshop. The oxidation profile is that the substrate is sealed after oxidation, while the electrophoretic profile is that the substrate is electrophoretic after oxidation and then solidified. The inner surface layer of the electrophoretic profile is oxide film, and the outer layer is electrophoretic paint film.

3. Oxidation profile and electrophoresis profile can be colored or not.

4. The passivation films of powder spraying and fluorocarbon profiles of our company are all finished by chromium free passivation process, without heavy metal chromium.

5. The products of electrophoresis, powder spraying, fluorocarbon paint spraying and three-dimensional wood grain spraying shall be cured.

6. Wood grain transfer printing can be carried out on the profile surface of electrophoresis, powder spraying and fluorocarbon. Most of them are powder coated wood grain transfer printing, while I have not seen the sample of fluorocarbon wood grain transfer printing.

7. The single profile of thermal insulation profile can be treated by oxidation, electrophoresis, spraying, fluorocarbon, wood grain, etc. There is no requirement for surface treatment of strip type thermal insulation profile, and the production process is the same; the punching process can be added to the injection type thermal insulation profile, which is mainly aimed at electrophoresis and fluorocarbon profile.

COMPANY:Fujian MingLv Aluminum Co., Ltd.

Contact:Mr. ZHENG

Tel:+86-0592-5718928

Phone:+86-13779947258

Email:120514135@qq.com

Add:No.44 hongcuoli, Dongren Road, Jimei District, Xiamen, China