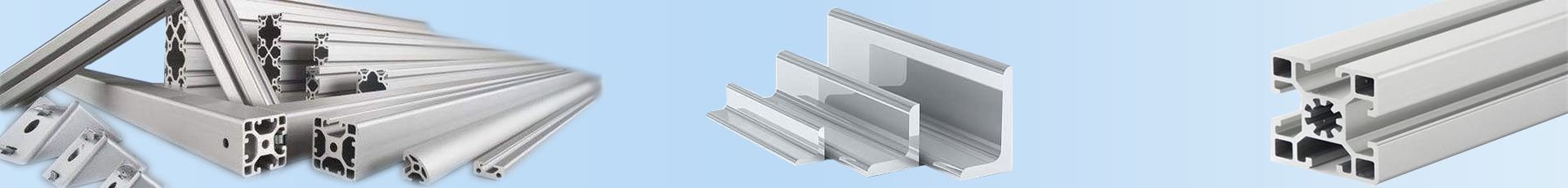

Nowadays, people pay more and more attention to health and environmental protection. But in the wood furniture industry, there is a basic problem that can not be avoided, that is, the indoor formaldehyde exceeds the standard. The manufacturing process of aluminum alloy floor is very simple. Usually, aluminum alloy is used as the base material for one-time die-casting or casting molding. The development of surface treatment technology and coating technology also provides a huge market competitive advantage for all aluminum floor for home use.

Aluminum alloy is the material for all aluminum household use. Aluminum is the most abundant metal element in the earth's crust. In recent years, all aluminum home is like an unstoppable "black horse", with its advantages of zero methanol, health and environmental protection, fire and insect prevention, recyclability, etc., it is gradually recognized by the industry and some consumers. Traditional furniture mostly uses wood, wood molding is much slower than aluminum, and the reserves and easy processing degree are all dominated by aluminum furniture, followed by the natural growth of wood and inevitable causes many defects.

1. Natural defects. Such as knots, oblique texture and defects caused by growth stress or natural damage. The branches included in the trunk or main branch of wood are called knots, which can be divided into dead knots and live knots according to the degree of continuous growth; and sound knots and rotten knots according to the material of knots. The twill of log is often called twist, and for sawn timber it is called twill.

2. Defects of biological hazards. There are mainly decayed, discolored and moth eaten.

3. Defects caused by drying and machining. Such as dry crack, warpage, saw cut, etc. Defects reduce the use value of wood. And aluminum is produced in blocks, not like the inevitable defects caused by wood in the growth process. Most importantly, all aluminum furniture is formaldehyde free.

In the market, the price of solid wood furniture is generally high. Driven by the interests, many people pretend to be solid wood furniture, but the final consumers buy real wood frame, joinery board, multilayer board, imitation solid wood, veneer, even high-density fiberboard furniture. In the process of making these synthetic boards, adhesives containing formaldehyde, benzene and benzene series are used, which can remain for 3-15 years, causing great harm to human body, and the release problem is also a big problem after people's home decoration. In addition, the harm of formaldehyde to pregnant women and children is especially serious, which also causes many tragedies and so on.

Wooden furniture: high formaldehyde is harmful to human body. Because of different technology, all aluminum furniture is made of plug-in, welding, screws and other fixed materials without adhesives. At the same time, it is a large extruded material, and it will not use a large number of adhesives when splicing wood materials, so there is no need to worry about formaldehyde. When the formaldehyde concentration reaches 0.06-0.07mg/m3 in the air per cubic meter, children will have slight asthma; when the formaldehyde in the indoor air reaches 0.1mg/m3, there will be peculiar smell and discomfort; when the formaldehyde reaches 0.5mg/m3, it can stimulate eyes and cause tears; when the formaldehyde reaches 0.6mg/m3, it can cause throat discomfort or pain. When the concentration is higher, it can cause nausea and vomiting, cough and chest tightness, asthma and even pulmonary edema; when formaldehyde reaches 30mg / m3, it will cause death. Symptoms of slight formaldehyde poisoning: obvious irritation of mucous membrane of eyes and upper respiratory tract. The main manifestations are conjunctival congestion, redness and swelling, dyspnea, heavy breathing sound, hoarseness of throat, speech or dry, dark dumb or greasy. The poisoned person can also feel his breathing sound bold. Another specific symptom of mild formaldehyde poisoning is one to two degrees of throat edema. Symptoms of severe formaldehyde poisoning: deterioration of lung and throat, pulmonary edema and fourth degree laryngeal edema, followed by serious blood gas analysis, is severe hypoxemia. All aluminum household solves the problem of cracking and deformation. Due to the characteristics of aluminum, its strength is much larger than that of wood. It completely solves the problem of cracking and deformation, adapts to a variety of environmental temperature with a small expansion coefficient, and has the advantages of fire prevention, moth proof, long-term blister does not rot. Wooden furniture is always easy to be damaged, the surface is scratched and damaged, and the wood paint falls off and explodes. The aluminum alloy material is not easy to deform, durable and not deformed. All aluminum home has a high ignition point (at least more than 600 degrees), which can play a good role in fire prevention and flame retardant, greatly reducing the casualties caused by the fire. Wood furniture is easy to light in case of fire, and does not have the effect of fire prevention and flame retardant. All aluminum household has a service life of more than 30 years, and it is durable, recyclable and recyclable, reducing environmental pollution. After the wooden home is in good condition, it needs to be replaced basically, and there is no recycling value.

COMPANY:Fujian MingLv Aluminum Co., Ltd.

Contact:Mr. ZHENG

Tel:+86-0592-5718928

Phone:+86-13779947258

Email:120514135@qq.com

Add:No.44 hongcuoli, Dongren Road, Jimei District, Xiamen, China