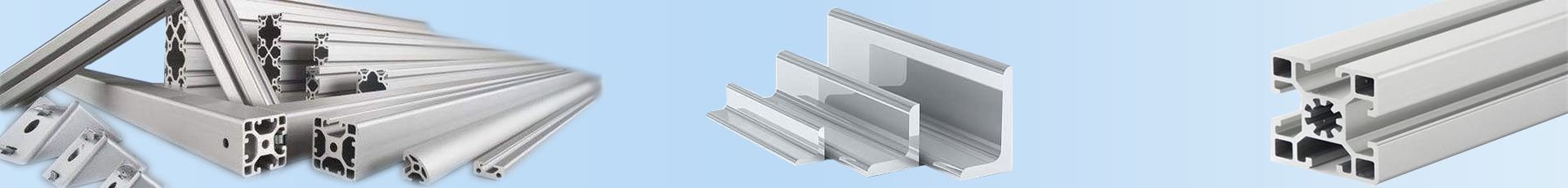

Aluminum profiles are extruded into a variety of hollow pipes. Aluminum alloy windows are the most representative in the home. Because of their good structural strength and beautiful surface treatment, they are often used in the field of electronic products.

So how is the finished aluminum profile processed?

Aluminum profile is a kind of aluminum tube material with different cross-section shape obtained by hot melting and extrusion of aluminum bar. The forming process mainly includes five processes: casting, extrusion, cutting, CNC washing and cutting, surface pretreatment and coloring

The following is the production process of aluminum profile products

[1] the main process of the first process of aluminum production is as follows:

Ingredients: according to the specific alloy brand to be produced, calculate the addition amount of various alloy components, and reasonably match with various raw materials.

Smelting: add the prepared raw materials into the smelting furnace according to the process requirements for melting, and effectively remove the impurities and gases in the melt by degassing and deslagging refining means.

Casting: the molten aluminum is cooled and cast into round bars of various specifications through deep well casting system under certain casting process conditions.

Note: this process is mainly to cast a round casting rod. Only with the round casting rod can the extrusion process be carried out. It is not to directly extrude aluminum profiles with metal liquid.

[2] extrusion is a kind of plastic processing method for the parts or semi-finished products which are placed in the mold cavity (or extrusion barrel) and pass through the high temperature metal embryo to exert strong pressure, force the metal embryo to produce plastic deformation and extrude from the mold hole of the extrusion die, so as to obtain the required section shape, size and certain mechanical properties.

Extrusion is a means of profile forming. First, according to the profile product cross-section design (stretch profile cross-section), and then make the extrusion die, use the extruder to extrude the heated round cast bar (or roll round cast bar) from the die. During extrusion, an air cooling quenching process and artificial aging process are used to complete the heat treatment and strengthening of hot aluminum profiles.

[3] cutting the extruded hollow aluminum tubes. After cutting, the shape of the product will be obtained. Finally, according to the local special requirements of the structural design, CNC washing and cutting will be carried out to obtain all the shapes of the final product structural design There are several cutting methods

1. Manual cutting machine

Manual cutting machine head can turn left and right, can cut 45 degree angle, cutting accuracy is poor, suitable for aluminum door and window industry and aluminum cutting work with low accuracy requirements.

2. Semi automatic cutting machine

A. the semi-automatic gas oil conversion high-speed aluminum cutting machine adopts tungsten inlaid steel circular saw blade for cutting, the spindle speed is 3200 rpm, the gas oil conversion is used as the feeding and pressing power of the machine, the hidden saw blade, the saw blade is cut from the bottom to the top, the automatic pressing and cutting, the machine automatically sprays oil and lubricates, the cutting material section is smooth and clean without burr, the accuracy is high, the single and multiple cutting can be realized, and the operation is simple and safe. B. the semi-automatic hydraulic aluminum cutting machine has rough structure. The machine uses oil pressure as the feed power, and the saw blade does parallel feed action. It has poor section accuracy of cutting materials and large cutting material size, which is suitable for aluminum rough machining, cutting and blanking.

3. Automatic aluminum cutting machine

It is suitable for small aluminum materials with large cutting volume and required precision. Small aluminum materials can be cut in bunches, multiple pieces can be cut at one time, with high efficiency. The machine has functions of feeding, clamping, positioning, etc. it is controlled by PLC to realize automatic cutting. Tungsten steel circular saw blade is used for cutting. The rotating speed of the saw blade is 3200 revolutions per minute. The cutting material section is bright and clean without burr. Suitable for all kinds of aluminum products manufacturing cutting accuracy requirements. Such as heat sink aluminum, U disk MP3 aluminum shell, aluminum tube, aluminum bar, aluminum alloy material cutting saw material

Note: when cutting the shape, you need to pay attention to whether you need high precision or bottom precision. If you need high precision, use a high precision cutting machine or CNC automatic cutting machine, otherwise the cutting surface of the product will be very rough and there are aluminum chips.

[4] if there are special structural parts in CNC washing and cutting, CNC (numerical control machine tool) is required to wash and cut them separately, such as drilling holes on the appearance surface, or sinking platform on the appearance surface, and high-precision cooperation is required for special parts.

Why choose CNC to do high-precision washing and cutting?

Compared with general machine tools, CNC machine tools have the following characteristics:

High machining accuracy and stable machining quality;

It can carry out multi coordinate linkage and process parts with complex shape;

When the machining parts are changed, generally only the NC program needs to be changed, which can save the production preparation time;

The machine tool itself has high precision and rigidity, so it can choose favorable processing amount and high productivity (generally 3-5 times that of ordinary machine tools);

The machine tool has a high degree of automation, which can reduce the labor intensity;

Mass production, easy to control product quality;

[5] the surface pretreatment uses chemical or physical methods to clean the profile surface and expose the pure matrix, so as to obtain complete and dense artificial oxide film. It can also polish the mirror surface by mechanical means or form sub surface effect by sand blasting or wire drawing

[6] coloring

Multi tone surface treatment aluminum profiles: silver white, tea, stainless steel, champagne, golden yellow, titanium gold, red series (wine red, jujube red, black, purple), etc. These profiles must be chemically or mechanically polished before they are oxidized for good results ---01. Anodizing---

The surface corrosion resistance of extruded aluminum alloy profile is not strong, so surface treatment must be carried out by anodizing to increase the corrosion resistance, wear resistance and appearance beauty of aluminum.. (so don't ask if you can make appearance parts without oxidation) the whole process of the product is: substrate → mounting → degreasing → alkali etching → neutralization → anodizing → electrolytic coloring → hole sealing → drying → unloading packaging → warehousing monochrome and gradual change: polishing / sandblasting / drawing → degreasing → anodizing → neutralization → dyeing → hole sealing → drying two colors:

① polishing / sandblasting / wire drawing → degreasing → shielding → anodizing 1 → anodizing 2 → hole sealing → drying

② polishing / sandblasting / drawing → degreasing → anodizing 1 → laser carving → anodizing 2 → hole sealing → drying

The following is the anodizing process: anodizing the surface pretreated profile, under certain process conditions, the substrate surface is anodized, forming a dense, porous, strong adsorption Al203 film The formation diagram of oxide film is as follows: the pretreatment diagram is as follows: the sealing principle diagram is as follows: the pores of porous oxide film formed after anodizing are sealed to enhance the anti pollution, anti-corrosion and wear resistance of oxide film. The oxide film is colorless and transparent. Some metal salts are adsorbed and deposited in the film hole, which can make the profile appearance show many colors other than the natural color (silver white), such as black, bronze, golden yellow and stainless steel.

COMPANY:Fujian MingLv Aluminum Co., Ltd.

Contact:Mr. ZHENG

Tel:+86-0592-5718928

Phone:+86-13779947258

Email:120514135@qq.com

Add:No.44 hongcuoli, Dongren Road, Jimei District, Xiamen, China